In the search for new strategies to reduce the heavy rare earth (HRE) content, in particular of Dy/Tb, and also for further lowering the manufacturing costs of sintered NdFeB magnets, some procedures have proved themselves to be suitable from a technical point of view.

Grain refinement is one of these procedures and used widely in manufacturing today.

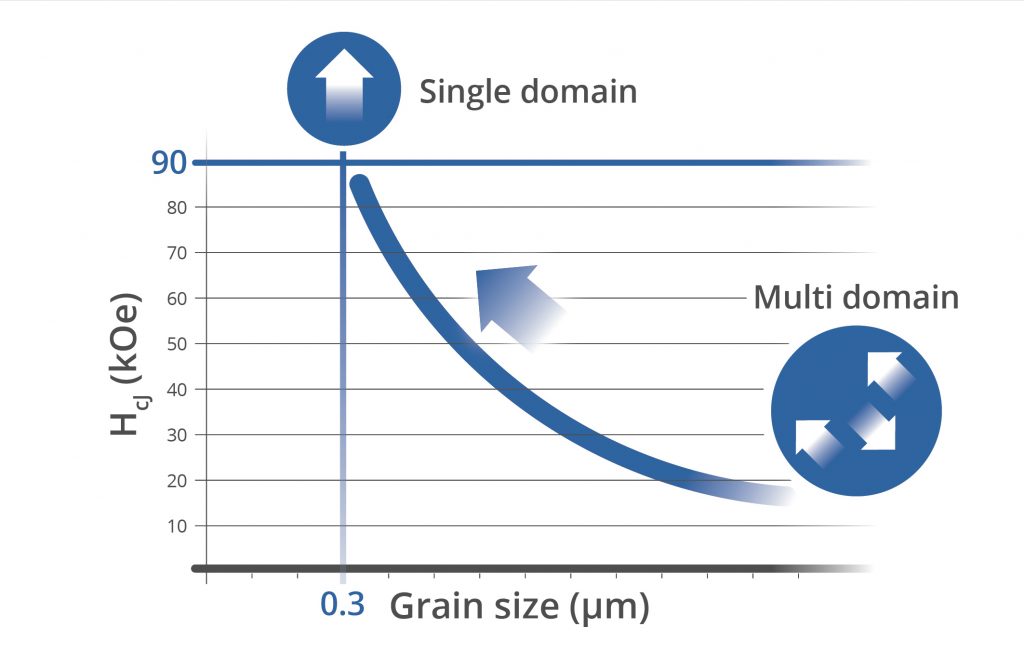

Theoretical as well as experimental results have shown that with the same alloy composition higher intrinsic coercive field strengths HcJ can be achieved with fine-grained magnet powder. By refining the grain size and optimizing the sintering process, the grain size of the magnets is reduced. This leads to an increase in the intrinsic coercive field strength HcJ of the magnet.

Grain Refining Technology is employed in order to use smaller quantities of HRE in fine-grained magnets and achieve a higher coercive field strength HcJ . This technology enables Yunsheng to mass produce the H and SH alloy groups.